CIMP: Cartridge Inspect, mark Pack Machine

A fully automatic stand alone LASER marking and packing machineLIVE Cartridges

Features:

• 300 cartridges per min

• Vision inspection for colour coded cartridges

• 10 watt air-cooled Yb Fibre Diode pump laser

• Final Inline Box assy, fill weigh and seal for total security

• Full diagnostic history for “pass & fail” and process verification

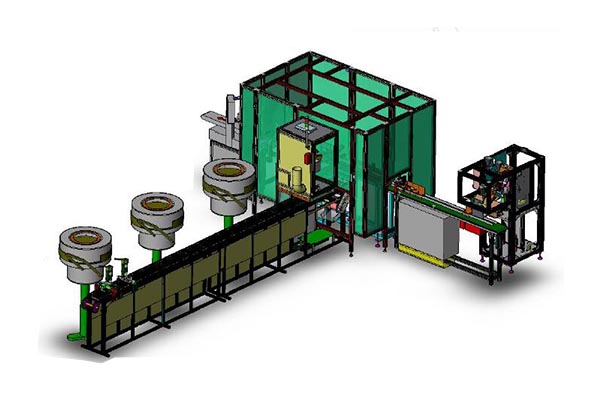

The CIMP: Cartridge Inspection, Marking and

Packing machine, is sub divided into 4 modules,

Cartridges feeder

A hopper fed dual track vibratory bowl 3 off, orientates and feeds the

cartridges into 6 off gravity fed stacker / ejector

Inspection station

Vision camera, to check colour of cartridge,

wrong colour is rejected .

Laser marking station

Cartridges individually marked with a

Diode laser, up to 900 characters per sec.

with a working area 157mm x 157mm with focal length of 254mm giving a spot diameter of 25μm. A camera is fitted

to verify marking is positive.

Packing Station (sealed)

Passed Cartridges are then of loaded and transferred into boxes each containing 50 rounds. Each box is weighed to

check quantity and sealed.